-

About Uschevron_right

-

Bending Divisionchevron_right

-

Plant Divisionchevron_right

-

Performancechevron_right

-

CS Centerchevron_right

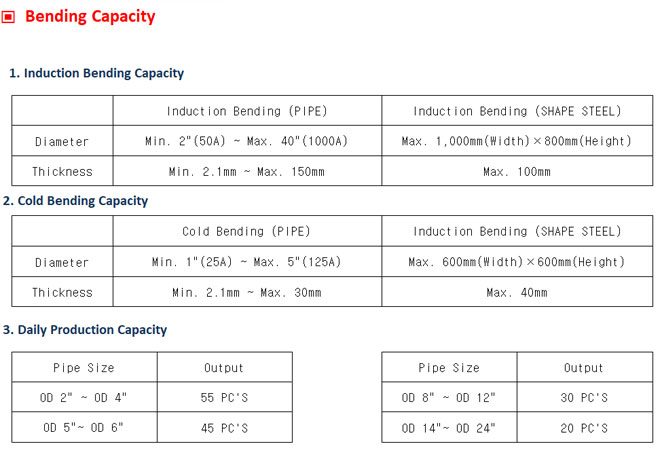

Bending Division

We manufacture reliable products.

KJ ENG pursues differentiated technology and customer satisfaction in the field of high frequency bending.

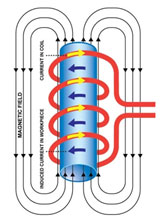

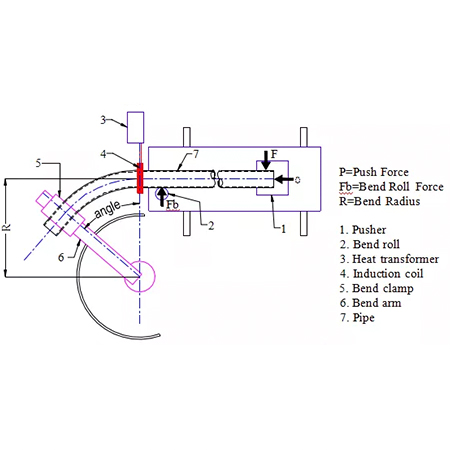

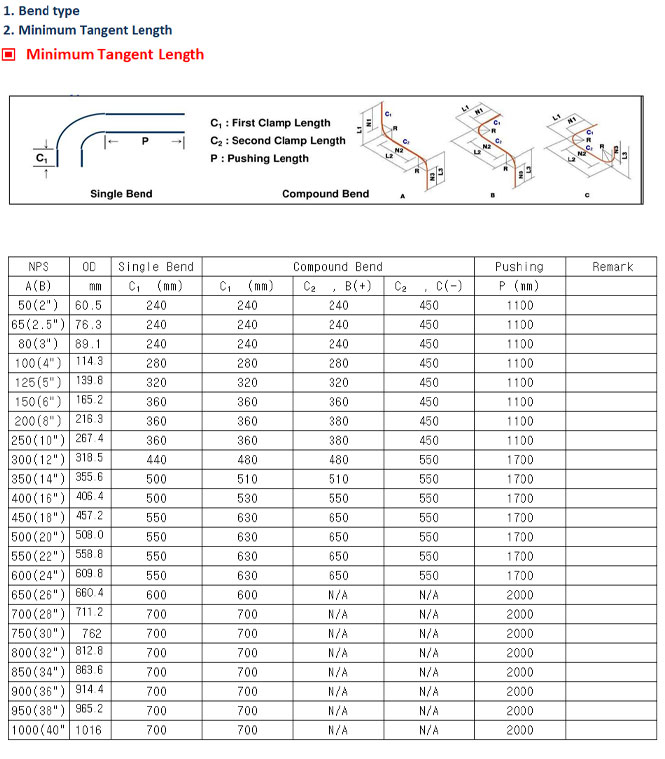

High-frequency bending is a hot working technology that bends various types of beams, such as pipes, H-beams, channels, and I-beams, using high-frequency induction heating. KJ ENG's advanced technology is being in various fields such as gas and petrochemical plants, thermal power and nuclear power plants, ship piping, structures, and civil materials. In particular, it can not only guarantee quality reliability in various fields such as pipelines of power plants that require high quality or inboard piping of ships where cost and delivery are top priority. It replaces the elbow and drastically reduces the number of welding man-hours, providing economic effects, shortening the construction period and improving quality.