-

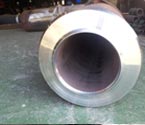

STEP 1

Material Inspection

Measurement

Ultrasonic Thickness Gauge

-

STEP 2

Induction Bending

Cold Bending

Highfrequency Induction Bending Machine

Bending Capacity: Max 32”×120t

-

STEP 3

Non-Destructive Examination(by MT)

Magnetic Particle examination For external Suface Of Bent Area

Examined by NDE Company

-

STEP 4

Post Bend Heat treatment(if Any)

electric Heat Treatment Furnace

-

STEP 5

Hydraulic Test(if Any)

Hydraulic Pump Capacity : Max. 350Kg/㎠

-

STEP 6

Marking and Cutting by Dwawing

Band Saw Machine : Max Dia. 40”

-

STEP 7, 8

End Bevelling And Hole Drilling

Non-Destructive Examination(If Any)

Boring Machine : MAX. 40”

Radial Machine for Hole Driling

-

STEP 9, 10

Final Dimensional and Visual

Inspection Hardness Test (If Any)

Steel Die : 12M×13M

Hardness Tester : Ecotip UCI Type

-

STEP 11

Auto Marking

Auto Punching Machine : MC2000 T2

-

STEP 12, 13

Packing

Transportaion